Surf Technology

EPS-EPOXY-CARBON STRINGER-FUSED CARBON WRAP

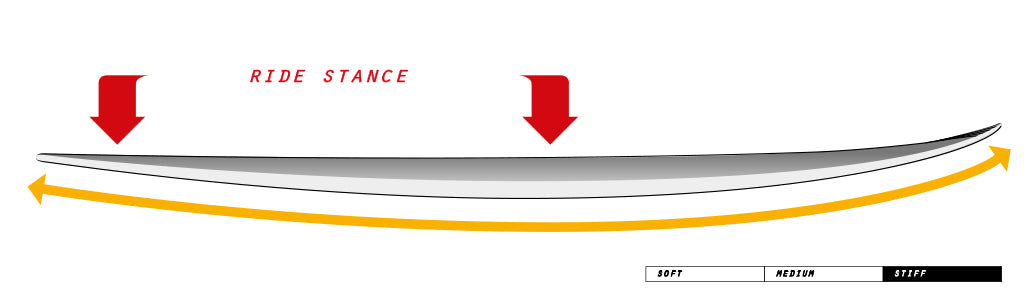

This surfboard construction is our latest and most advanced eps epoxy fused carbon stringer technology. There is a tremendous amount of research and ongoing development realized in this technology and we are pursuing the patent as no other surf brand has yet to come up with this type of surfboard construction. The core is a 23kg/m³ EPS high density 100% recyclable foam, produced from 98% air and only 2% petroleum products, which makes for a very responsive, agile and lively feeling but does not feel like the board over floats as with other epoxy technologies. The cutting edge construction used for the stringer of the surfboard is a uni-directional 3k carbon tape*. In the glassing process on the bottom and deck side of the finished blank we place a fused carbon tape for excess endurance and increased momentum flex characteristics. We use one sheet of 4oz fiberglass cloth on the bottom side to keep the board light weight and responsive. On the top side we use two sheets of fiber glass so as to ensure extra strength and durability were its needed the most. The fiber glass is coated in fast curing Kwik epoxy resins which are produced from 75% recyclable approved materials, with UV additives to ensure greater durability and protection against the sun. Futures or FCSII fin plugs are attached depending on rider preference.

PATENT PENDING

*Purpose built for Cohete Surfboards by Shapers:

- FLEX SYSTEM

- SUSTAINABILITY